An interesting development over the last decade or so, is the rising importance of arc flash studies. There is a variety of reasons for this, but it is mainly due to the recognition that arcing faults present a particular hazard to operational staff, that is frequently overlooked – potentially putting personnel in danger. Arcing faults are one of the more common types of faults that can occur, and are often associated with maintenance activities such as racking in/out breakers.

So what does an arc flash study do? In simple terms, it works out the amount of incident energy that could occur at a specific distance from the switchgear (i.e. where the operator would be standing), if an arcing fault were to occur. This level of incident energy is expressed in Cal/cm2 and is then used to determine the level of PPE that an engineer must wear, when carrying out switching duties.

one of the interesting problems facing the UK and Europe is that there is no IEC standard for working out the incident energy levels. The accepted industry standard practice is an American standard called IEEE1584 standard for Arc Flash calculations. It is common also to hear reference to the NFPA 70E standard, but for design purposes, this really just refers back to the IEEE 1584 standard and gives a few optional look-up tables where no design information is known. The IEC 61482 standard is only applicable to the testing method for the various flameproof garments.

The typical energy levels and required PPE (for the UK) are summarised below (extracted from IET Health Safety Briefing note 51c) :

| Energy Level |

Energy Level

(Cal/cm2) |

PPE Description |

| 0 | 1.2 | 1 layer of untreated cotton long sleeve shirt and trousers (covering all the body), polycarbonate safety spectacles, lightweight gloves. |

| 1 | 4 | Cotton undergarments, 1 layer flame retardant (FR) work wear, helmet, polycarbonate safety spectacles, lightweight FR gloves. |

| 2 | 8 | As above, but with 2 layer FR outer work wear that has wrist closures and a full face polycarbonate visor. A FR single layer balaclava may also be worn.As above, but with 2 layer FR outer work wear that has wrist closures and a full face polycarbonate visor. A FR single layer balaclava may also be worn. |

| 3 | 25 | 3 layer FR outer work wear with cotton under garments and FR shirt, a full face hood or visor with safety spectacles underneath, chrome leather gauntlets. |

| 4 | 40 | Typically 4 layer FR outer wok wear, FR and electrically insulated footwear and suitable FR material spates to close off the ankle area, FR gloves or chrome leather gauntlets, a hood constructed from a trip later of FR material with a sewn-in polycarbonate face shield within a minimum of 2 panels of suitable thickness with one coated with a gold film for UV protection. |

| X | 40+ | Not usually permitted

|

It can be seen from above that Energy levels above 8 Cal/cm2 become very problematic for operators, as a high level of PPE is required, which can become very cumbersome to wear.

The next question is obviously – how is the arc flash incident energy level calculated? This is a rather complex question, that would need a long read of IEEE 1584 to understand fully – but essentially it comes down to three things. 1) The fault current and 2) The protection clearing time and 3) the various clearances between the live conductors, the switchgear and the operator. These three factors (along with other correction factors) form part of a formula that is used to calculate the incident energy levels. In practice, the clearances between the conductor and operator are fixed depending on the make & model of the switchgear and are not something that can really be specified.

The other two factors remaining are therefore the fault current and protection clearance time. These two factors are things that can be controlled easily during the design stage, but once equipment is constructed they are very difficult to change. Let’s discuss these factors in turn.

Fault level – this is perhaps the most obvious issue. Where a system has a high fault level in kA, then the corresponding incident energy levels will be high. So in order to reduce the incident energy levels it is necessary to reduce the fault level – how is this done? Well practically it means choosing smaller transformers, or specifying transformers with higher impedances. For example a 2.5MVA, z=6% transformer will have a worst-case LV (400V) fault level of (2.5MVA/0.06)/(sqrt(3) *400)= 60.1kA, a 1.6MVA transformer, z=6% in the same case will have a fault level of (1.6MVA/0.06)/(sqrt(3)*400) = 38.5kA. From a design perspective, using smaller transformers reduces the fault level and arc-flash risk, but means that you would need more transformers, more space and more cost to supply the same amount of power. Similarly fault limiting MCCBs and fuses, can also help reduce the fault level down. Are these approaches an acceptable trade off? It depends on the project!

Protection Clearance Time – This is a slightly more subtle concept, but the longer the arc remains on the system the higher the incident energy level that occurs. In practice the protection clearance time will be defined by the type of protection relays used. Simple IDMT over-current relays, will clear a fault far more slowly than differential protection, and thus results in a higher incident energy level and risk to personnel. From a design perspective, this can be controlled through specifying full or partial differential protection systems on main switchboards – in the UK this is something that is not commonly done except on switchboards rate at 33kv and above and so 11kV switchgear can present a significant risk, as the protection relays will tend to operate slowly, as they have to co-ordinate with the LV network.

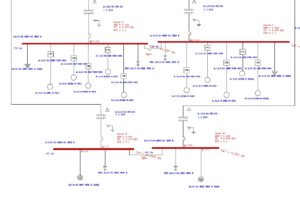

A sample results from an Arc Flash study carried out in ETAP can be seen in the Figure below. This figure shows the results of two switchboards (one MV and one LV) of a much larger switchboard. In this example the MV switchboard has an Incident Energy Level of 5.5kA and an Energy Level of ‘C’ (equivalent to UK level 2), whilst the LV switchboard has an Incident Energy Level of 2.1kA, and an Energy Level of B (equivalent to UK level 1). These results are both acceptable, and are based on estimated Fault Clearing Times of 0.1s, if this figure was increased, then the I.E. values and Energy levels would increase correspondingly.

Figure 1 – Arc Flash Study Results

In practice, carrying out an arc-flash study can only be done using sophisticated computer simulation packages such as ETAP or Digsilent. For the simulations to work properly, it is also necessary to fully model the entire protection system, to correctly identify the fault clearance times. This is usually impractical in a concept design and the studies engineer must estimate typical protection clearance times, based on the proposed protection scheme. As noted earlier though, it is possible to set generic Fault Clearance Times (FCT), although this is usually only recommended during early concept stages.

In summary, arc-flash analysis is an important calculation which is necessary to define the required PPE of operational staff. The amount of incident energy is a function of several variables, of which fault level and time are key parameters which can be controlled by a designer – what this means is that some systems with a high fault level but a fast fault clearing time, such as differential protection can actually pose less risk than a system with a lower fault level and slow protection clearing times. As a designer there are various parameters that can be adjusted to help reduce the incident energy levels, but they carry a cost which must be justified.

If you would like to know more – please contact us!